Manufacturing Capabilities

Three generations of manufacturing experience, diverse skills, precision CNC turning and CNC milling expertise, and the use of advanced manufacturing and production systems enable us to provide our customers with parts and assemblies of better quality, for a reduced cost and better lead times. Bracalente Manufacturing Group offers a multitude of services and machining solutions including:

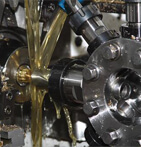

Precision CNC Machining

Utilizing the latest CNC turning, machining centers, arrays of multi-axis machining capabilities, and state-of-the-art CAD/CAM software, we accurately accommodate many levels of precision and volume. We can produce complex parts with elaborate geometries and deep holes from even the most difficult to machine metals.

Our US & China facilities utilize a range of standard and advanced CNC equipment, such as:

HYBRID CNC 6 SPINDLE SCREW

These machines combine the capabilities from classic-style screw machines and modern CNC lathes. The combination of the two creates a machine that can single point threads, contour single point turn and bore as well as form, pick off and back work. These machines are also equipped with High Pressure coolant.

ROTARY TRANSFER

Our horizontal and trunnion-style rotary transfer machines are simple, flexible and efficient machining centers where we perform various operations including drilling, cross drilling, boring, turning, milling, threading, tapping and broaching. The result is consistent quality, efficiency and productivity with little or no need for secondary operations.

SWISS TURNING

We offer a variety of CNC Swiss machining services for orders with diverse production material, tolerance and volume requirements. Our superior precision machining capabilities allow us to create small precision parts that are trusted in a number of industries. We provide advanced technology for all of your needs, from boring and milling, to thread cutting and polishing.

MULTI-SPINDLE

At BMG multi-spindle machining is the flagship of efficiency. Equipped with secondary machining attachments that allow these productivity workhorses to compete in today’s workplace, BMG’s multi-spindle automatics are able to produce parts in short to medium runs that need little, if any, secondary machining before they are ready for delivery.

AUTOMATIC SCREW

For more than 50 years we have used automatic screw machines in the production of small to medium-sized turn parts. Our vast experience as well as our investment in upgrading and purchasing new and improved screw machines allows us to expertly and inexpensively produce a variety of quality high-volume turned components.

Secondary Operations

Producing complex, precision parts requires control over the entire production process in order to consistently deliver high-quality finished parts. Secondary operations we offer include:

- Broaching

- Deburring

- Drilling

- Finishing

- Grinding

- Milling

- Sawing

- Specialty Parts Cleaning

- Stamping

- Tapping

- Thread Rolling

Manufacturing Solutions

Our company compliments our machining services with a number of manufacturing solutions from engineering to outsourcing:

VALUE ADDED ENGINEERING

BMG manufacturing engineers come from diverse backgrounds within a variety of disciplines. As a result, we can talk the language of your industry, understand what you need to build, prototype or optimize high volumes, plan deliveries or manage production. We will help you to solve all of your problems.

TOOL DESIGN

Using the advanced solid modeling and 3D design capabilities of SolidWorks computer software technology, our knowledgeable, highly-skilled tool designers are able to create innovative custom workholding fixtures that allow your part to be manufactured precisely, consistently and economically.

TOOL MAKING

Working from your finished drawings, your concept sketches, or a design we have created for you, BMG’s in-house tool making department manufactures high-precision tooling and components using a wide variety of processes including Wire EDM, CNC turning, surface and form grinding, and EZ TRAC Bridgeport milling.

ROBOTICS & AUTOMATION

Employing the use of robotics and automation systems enables our company to operate at its maximum potential. Automation exists on many levels within Bracalente Manufacturing Group. From the art of moving parts across the shop floor, to the way parts move inside our sophisticated machining centers, there is an element of automation in everything we do.

ELECTRO MECHANICAL ASSEMBLY

BMG provides complete turnkey capability to manufacture electro-mechanical assemblies. Our multi-faceted electro-mechanical assembly services are industry compliant and meet absolute client satisfaction. Be sure to contact our team for any questions you may have regarding this advanced assembly service.

GLOBAL SOLUTIONS

Our wholly-owned foreign enterprise in Suzhou, just west of Shanghai is a state-of-the-art facility with 32,000 ft² of manufacturing space, equipped with modern CNC equipment, an assembly area, a BMG managed/trained work force and personnel in the factory to insure quality at every step of the process.

OUTSOURCING PARTNERS

When a customer part or assembly leaves our shop for processing at another company’s location the rules remain the same – we provide a level of quality in products and services that meets or exceeds the expectations of our customers. Some outsourced services we manage include: painting, powder coating, & hard coating, heat treating, welding, gear cutting, and fabricating.

Quality Capabilities

Quality is behind every process we employ and inside every part we produce. From our initial quote, through manufacturing on the factory floor, to shipping finished customer parts and assemblies around the world – we work to assure the high quality of everything we do.

- ISO Certification – As an ISO 9001:2008 certified organization BMG can prove its manufacturing competence and consistent performance to ensure everyone can have confidence in the quality of parts and assemblies we produce.

- Quality Management – Our commitment to manufacturing excellence is the foundation on which our business is built. So it makes sense that quality and continuous improvement would be at the heart of everything we do – in the processes we employ, in the products we produce, and the services we provide.

- Statistical Process Control – Statistical Process Control (SPC) is part of the continuous improvement culture at BMG. All of our manufacturing employees and quality technicians are equipped with the knowledge and the tools to locate, analyze and control the sources of variability in our production processes.

- Gage Calibration – Bracalente produces a wide variety of parts and assemblies in all shapes and sizes from many different metals according to hundreds of customer specifications. It takes more than 5,000 measuring instruments throughout our facility to ensure those parts and assemblies are produced to precise and repeatable tolerances.

- Inspection – Aside from developing and implementing quality plans for every job that goes through our facility, BMG’s inspection team also supports the following activities: FAS (First Article Samples), ISIR (Initial Sample Inspection Reports) and PPAP (Production Part Approval Process).

Supply Chain Management

BMG recognizes SCM as an essential element to operational efficiency. We offer a single point of contact, focused on getting the right part, in the right condition, to the right place, at the right time. Utilizing our systems, procedures, networks, ERP, internet and EDI, we increase our efficiency and reduce the cost of procurement for our customers.

US SUPPLY CHAIN MANAGEMENT

BMG has established strategic partnerships with best-in-class suppliers. Suppliers are selected through a formal process of onsite audit and interview; regular visits from BMC Quality personnel ensure good lines of communication. Suppliers’ performance is documented and reported in key business metrics.

GLOBAL SUPPLY CHAIN MANAGEMENT

All approved global suppliers are visited regularly by BMC US personnel and BGL Supplier Quality Staff for audit and communication. Quad charts are maintained on all global suppliers to plot their progress. Full-time BGL Supplier Quality personnel are resident in key suppliers. Suppliers’ performance is documented and reported in key business metrics.

Business Systems Capabilities

Utilizing leading edge synchronized business performance tools, ERP, automated electronic transactions, EDI, LEAN, integrated quality, procurement, planning and scheduling enables us to provide our customers with world-class service.

- ERP – Bracalente’s ERP system, Vantage by Epicor Software Corporation, enables us to meet the continuing challenges of both domestic and global growth: cost, quality and response time.

- GAINsharing – GAINsharing is an incentive system that involves all BMG employees in the improvement of organizational performance. It measures the level of improvement and shares the financial value of the “GAIN” with participants.

- LEAN Manufacturing – BMG has harnessed the power of Lean manufacturing to improve product quality. In addition, through LEAN we reduce manufacturing lead times, enhance customer service and create a better work place.

- Green Energy – Rapidly changing solar, oil, hydroelectric, and wind power industries require parts of incredible precision and durability. We are continuously developing faster, cost-effective ways to machine increasingly complex parts, with more stringent tolerances.

Logistics Capabilities

From the procurement of materials to the timely delivery of finished products anywhere in the world, BMG and our partners are second to none in logistics management.

- Materials – Advances in materials science, machinery and tooling continue to broaden the range of materials we machine. Sixty years machining experience and continuous education allows us to expertly match processes, machines, materials, speeds and tooling. Among others we work with: Aluminum, Beryllium, Brass, Bronze, Copper, Hastelloy, High-Temperature Alloys, Monel, Stainless, Steel, Titanium and Tungsten.

- Packaging – Bracalente has significant experience in supplying packaging solutions that meet the various requirements of our many customers. We offer custom designed packaging to your specifications, as well as compliant packaging for both domestic and international shipments. We work closely with our customers to develop returnable packaging programs and other solutions aimed at saving time and expense.

- Shipping & Receiving – At Bracalente Manufacturing we put as much care in shipping finished parts and assemblies as we do in the way we manufacturing them. Whether we’re shipping around the corner, around the world, or anywhere in between – we work to ensure your order arrives on time and intact.