From self-driving vehicles to fuel-efficient, hybrid cars, the electric vehicle industry continues to innovate the driving experience.

Bracalente brings precision machining to a whole new level. With more modular systems, regulatory pressure and increased competition, we have been building precision component parts for foreign and domestic manufacturers. We provide solutions to these technological advances by offering a solid supply base footprint and cost efficiencies to meet the market’s ever-changing demands.

- Concept drawings, prototypes, real-time inventory management

- Precision machined components

- On-time deliveries

- Lights-out manufacturing facility

- Capacity for quick turnaround

- Global supply chain

- Lean manufacturing facilities in the United States and China

- Design for Manufacturing (DFM)

We specialize in:

- Chargers (mega, super, residential, DCFC; Direct Current Fast Charging)

- Level 2 charging

- Battery (pack, cell, module)

- AFID (Alternative Fuel Infrastructure Directive)

- LDV (light duty vehicle)

- BEV (Battery Electric Vehicle)

- ZEV (Zero Emissions Vehicle)

Bracalente Certifications

- ISO 9001:2015

- IATF 16949:2016

- AS9100D

- ITAR

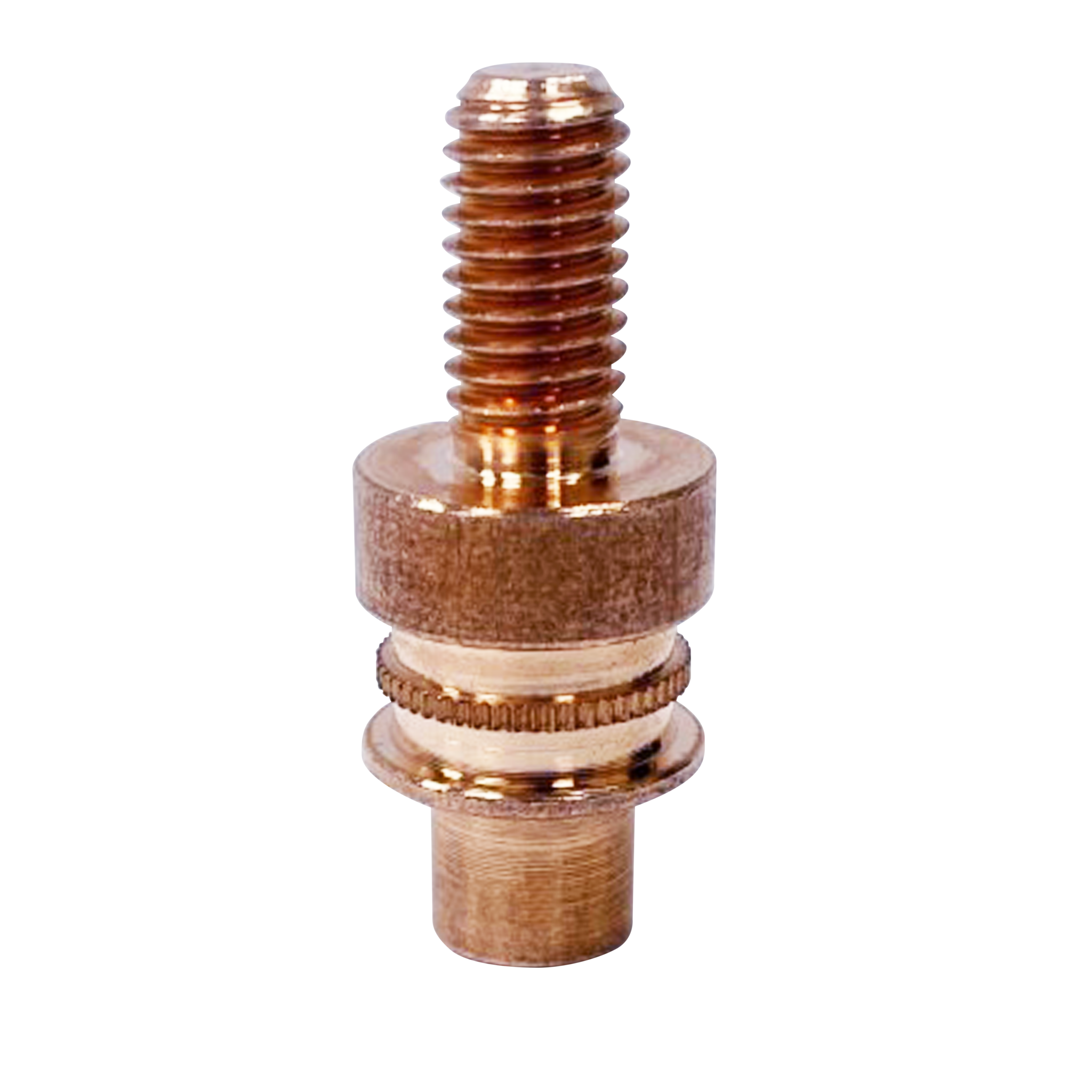

Components

SCREW MACH

SCREW MACH

Machining Capabilities

With lights-out machining, 70 years+ of precision manufacturing, industry experts, global sourcing and redundancy, we have the capacity and experienced relationships in our network to flex for whatever your project requires. The Bracalente Edge™ allows us to leverage the highest standards in technology, innovation, quality and cost that delivers on time, every time.

Tornos Multi-Swiss

This is one of the most advanced machine tools in our organization and will allow us up to 20% efficiency gains due to its lights out production (LOOP) capabilities.

CNC Turning

Using robotic automation and tool load censoring to optimize tool life, we are capable of producing fully completed pieces with a high degree of precision. Between our two lean manufacturing facilities in the United States and China, we operate more than 75 CNC Turning Machines.

We are capable of upholding tolerances as close as ±0.00025″

MMC2 System

Our MMC2 system ties individual horizontal machining centers to an automated pallet system to enhance productivity. Through technology and innovation the system provides built in automation, lights out production (LOOP), efficiency and flexibility, cost improvements and reduces set up time for the customer.

Materials

Typical materials include copper, aluminum, brass, bronze, carbon steel, stainless steel, and high temperature alloys.

Diverse Clients

Case Study

Global Manufacturer of Hybrid Vehicle Motors

Industry: Automotive

A global manufacturer of motors for hybrid electric vehicles was referred to Bracalente to help with a motor mount issue they were having with a supplier in China.